|

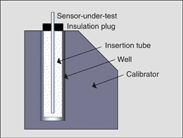

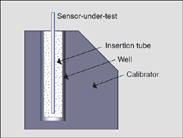

Using inserts from other JOFRA calibrators: Often customers believe that they can use inserts from other models of JOFRA temperature calibrators. Consequenty, we get complaints about errrors in the temperature specifications. Even if the diameter is right, the length might not be. In this case the insertion tube is too tall. This gives a heat flow out of the top of the well and the temperature uniformity will change dramatically. |

|

Using

inserts that are too small: Using insertion tubes with diameters that are too small creates another problem. The heat transfer between the well and the insertion tube is insufficient, as the air around the tube has an insulating effect. This will make the temperature very unstable and unable to reach the set value. This problem also applies to the use of 6 mm and 1/4 in (6.35 mm) sensor holes. Even though this combination may seem to match it gives a very poor heat transfer as the sensors do not have an even contact with the insertion tube. |

|

Using

inserts made of the “wrong” material: Home-made inserts can be made in a very professional way with the correct lenght and size, but the material used for the inserts might cause problems and wrong results. If the specifications e.g. apply to a brass insert, it is not a good idea to use inserts made of aluminum or other materials due to the difference in conductivity. To get the right result and to make the calibrator measure correctly, it is therefore extremely important to use the right material for the inserts. |

|

Using

inserts with too short sensor holes: When drilling your own inserts it is a common mistake to make the sensor holes too short. Using this kind of insert may influence the temperature gradient, as the calibrator was originally calibrated at the bottom of the well. |

|

Using

inserts without using an insulation plug: All JOFRA cooling temperature calibrators are delivered with an insulation plug, to be placed on top of the well. The design of this type of calibrators require such a device, and the calibrators have also been calibrated with the insulation plug. There is a large heat flow out of the well, and if the plug is not used during calibration, it will cause problems reaching the set temperature of the calibrator. |

|

Using inserts

with the correct size, holes and material: To avoid problems, waste of time and to get the optimum use of your calibrator we recommend that you use inserts from AMETEK Calibration Instruments as they follow our specifications. |