TOPIC:"High Performance" Instrument ValvesAnderson Greenwood - AGCO |

||||

|

Many

years of Instrument Valve product development and

improvement have yielded design features

when combined in one unit provide a true "High Performance" Instrument Valve. |

||||

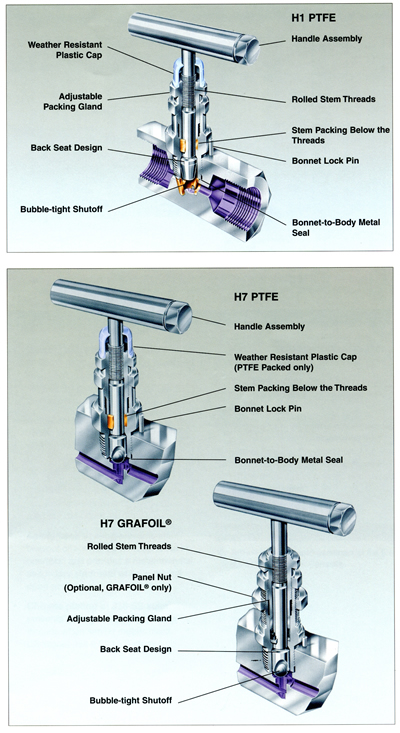

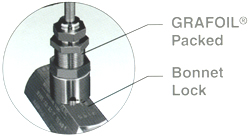

| BONNET TECHNOLOGIES |

|

|||

|

||||

| SEAT TECHNOLOGIES | ||||

|

||||

| INSTRUMENT VALVES PER ASME B31.1 POWER PIPING CODE | ||||

|

||||

|

|

|||

|

||

|

Minimize Gauge Line Error |

||

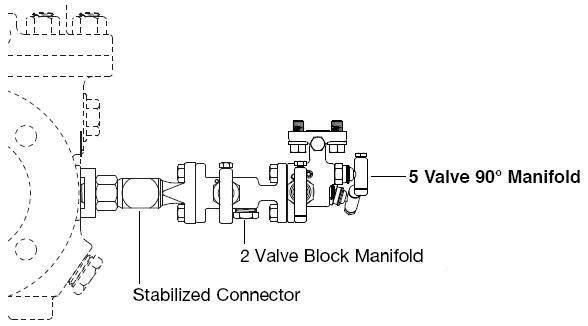

| Close coupled direct mount systems were developed in response to requests by leading gas transmission companies for a safe, efficient method of close coupling EFM's and transmitters to orifice fittings. The need for close coupling was established through studies conducted by the Southwest Research Institute and sponsored by the Pipeline and Compressor Research Council, which proved the existence of flow and/or pulsation-induced Gauge Line Error (GLE) in traditional, remotely tubed meter installations. The research concluded that GLE can be minimized by mounting metering instruments directly to the orifice fitting, using constant diameter large bore manifolding. | ||

FOR BEST ACCURACY |

|

|

|

||

FOR BEST PERFORMANCE |

||

|

||

Anderson Greenwood

Instrument Valve Catalogs

| Description | Size |

| 2.1 MB | |

| 1.9 MB | |

| 6.9 MB | |

| 0.8 MB |